FLOTECH METAL ALLOY INC IS LEADING MANUFACTURE, EXPORTERS, STOCKIST, SUPPLIERS OF TITANIUM GR2 SEAMLESS PIPE,TITANIUM GR2 ROUND BAR , TITANIUM GR2 FLANGES ,TITANIUM GR2 SHEETS & PLATES , TITANIUM GR2 PIPE FITTINGS ,TITANIUM GR2 FASTENERS.

Flotech Metal Alloy Inc, Maharashtra, Mumbai, India are leading dealer, supplier, exporter, wholesaler, trader, retailer & stockiest for Titanium GR2 pipe, tube, bars, sheet, coils & plates in India.

Titanium Grades 1, 2, 3 and 4 are commercially pure (99% minimum titanium). Each grade has slight variations in chemical composition that affect mechanical properties and design capability. The corrosion resistance is similar across all four grades.

FLOTECH METAL ALLOY INC IS LEADING MANUFACTURE, EXPORTERS, STOCKIST, SUPPLIERS OF TITANIUM GR2 PIPES.

We have to ensure that all our Titanium products offer the utmost strength, durability and reliability amongst extreme environments. The ability of this alloy is the reason for its major use in oil and gas, offshore and in the aerospace industries. These Titanium Grade 2 Seamless Pipes are supplied as ASTM B861 UNS R50400 and as per ANSI B36.19M and ANSI B36.10. A pipe without a seam or weld is known as Seamless Pipe. UNS R50400 Seamless Pipes can withstand high mechanical stress and high pressure can work in high temperatures and corrosive environments. Titanium 2 Seamless Pipe is formed by drawing a solid metal billet over a piercing rod to create a hollow tube. Seamless Pipe is then processed and finished as per dimension standard ANSI B36.10 and ANSI B36.19 and B36.19M in different wall thickness and sizes ranging from SCH 5S to SCH XXS. Titanium Grade 2 Seamless Pipes have varied applications in the Oil and gas, Chemical, Pharmaceutical, Fertilizer, Agro-Chemical, Aerospace, Desalination, Food and Beverage, Sugar, Distillery, Power Generation, Cement, Petroleum Refinery, mechanical and structural, food processing, etc.

| Size | ½” to 6” NB Sch 10s, 40s, & 80s, 160s |

| Wall Thickness | 0.1 - 60 mm |

| Titanium Gr 2 pipes Length |

|

| Surface Finish | Cold Finish, Bright, Polished, Annealing, Pickling, or as per client requirements |

| Standard | JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST |

| Titanium Gr 2 pipes Manufacturing types | Seamless, Welded, ERW, EFW |

| Manufacturing Shapes | Round, Square, Rectangle, Box Section |

| Titanium Gr 2 pipes Manufacturing Technology | Hot / Cold Formed |

| Inspection, Test Reports | EN 10204 3.1, Mill Test Certificates, PMI Test Reports, Chemical Reports, Mechanical Reports, NABL Approved Lab Reports, Visual Inspection Reports, Destructive and Non Destructive Test Reports, Third Party Inspection |

| Titanium Gr 2 pipes Technique | Cold Rolled Hot Rolled |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 39900 , MPa – 275 | Psi – 49900 , MPa – 344 | 20 % |

| Titanium Gr 2 | C | Ti | N | Fe | H | O | V | Al |

| 0.1 max | 99.2 min | 0.03 max | 0.3 max | 0.015 max | 0.25 max | – | – |

FLOTECH METAL ALLOY INC IS LEADING MANUFACTURE, EXPORTERS, STOCKIST, SUPPLIERS OF TITANIUM GR2 ROUND BARS.

It is extremely resistant to caustic alkalis up to and including molten state. Titanium WNR 3.7035 Flat Bars is utilized in the manufacture of benzene, methane, and ethane, as well as in reactors and containers. And so its used in the production of soap and viscose rayon. At temperatures exceeding 315 degrees Celsius, the tensile strength and elongation of this alloy decrease dramatically (600 Degree F). It is also utilized in the electrolysis of caustic soda from salt solutions and subsequent concentration operations. Ti-Alloy Gr2 Threaded Bars should be annealed at temperatures ranging from 1300 to 1600 degrees Fahrenheit. Such product, which stands out for its low C-concentration, is preferable at application temperatures over 300° C (572° F).

| Dimensions | DIN, EN, ASTM, JIS, ASME, BS, AISI |

|---|---|

| titanium gr2 Round bars size | Diameter: 3-~800mm |

| Flat bars size | Thickness: 2 -100mm |

| Width: 10 to 500mm | |

| Angle bars size | 3mm*20mm*20mm~12mm*100mm*100mm |

| Channel bars | 80 x 40mm to 150 x 75mm section; 5.0 to 6.0mm thickness |

| Rectangular barss Section | 3.0 to 12.0mm thickness |

| Billet Size | 1/2 to 495mm Diameter |

| Rectangles Size | 33 x 30mm to 295 x 1066mm |

| Hollow bars | 32mm OD x 16mm ID to 250mm OD x 200mm ID) |

| Titanium Gr 2 Round bars Dimensions | Diameter / Height: |

| Tolerance | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish | Cold (bright) drawn, centreless ground, hot rolled, smooth turned, peeled, slit rolled edge, hot rolled annealed, Rough Turned, Bright, Polish, Grinding, Centreless Ground & Black |

| Titanium Gr 2 Round bars Surface | Hot Rolled Pickled, Bright, Sand Blasting Finished, Cold Drawn, Hairline,Polished |

| Condition | Hardened & tempered, annealed |

| Titanium Gr 2 Round bars Technique | Stainless Steel Cold Drawn, Hot Rolled, Forged Round bars,Cold Rolled, Rod |

| Processing | bars cutting to 650mm |

| Titanium Gr 2 Round bars Form | Rod, Round, Channel bars, T-bars, Flat bars, Precision Ground bars, Blocks, Square, Rings, Round Rod, Triangle, Hollow, Rectangle, Threaded, Hex (A/F), Profiles, Half Round bars, Ingot, Billet, I/H bars, Forging etc. |

| Grade | C | N | O | H | Ti | Fe |

|---|---|---|---|---|---|---|

| Titanium Gr 2 bar | 0.10 max | 0.03 max | 0.25 max | 0.015 max | bal | 0.30 max |

| Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

|---|---|---|---|---|

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 35000 , MPa – 240 | 40 % |

FLOTECH METAL ALLOY INC IS LEADING MANUFACTURE, EXPORTERS, STOCKIST, SUPPLIERS OF TITANIUM GR2 FLANGES.

Titanium Gr 2 Flanges can perform well in marine environments because of their chemical composition. With the content of copper ranging between 28% to 34%, it is referred to as a superalloy for its good corrosion resistance properties. Preferred by many a Monel Flanges Manufacturer In India, this alloy exhibits high tensile strength making it a commercially viable option for marine engineering purposes. The Wnr 2.4360 Reducing Flange is resistant to chloride stress corrosion cracking, which is a common issue in marine environments. Like many nickel containing alloys, the performance of this alloy supersedes many conventional stainless steel alloys at elevated temperatures. The functionality of the Astm B564 Uns N04400 Pipe Flange is so great that its mechanical properties remain unaffected despite exposure to a temperature as high as 1000° F. Usually, the production of these components is made possible by annealing. The drawback of this annealing this alloy is that the strength of the Nickel Alloy 400 Forged Flanges remains low.

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique |

|

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi - 35,000 , MPa - 240 | Psi - 80,000 , MPa - 550 | 40 % |

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | – | – |

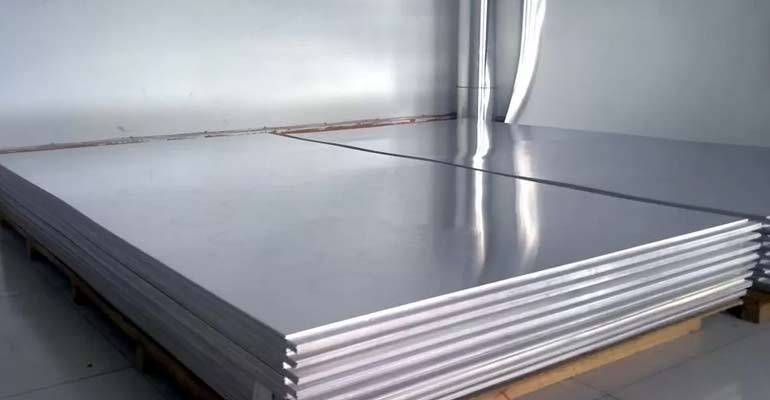

FLOTECH METAL ALLOY INC IS LEADING MANUFACTURE, EXPORTERS, STOCKIST, SUPPLIERS OF TITANIUM GR2 SHEETS & PLATES.

The Alloy 400 sheet is used in feed water and steam generator tubing, cladding of oil refinery crude coloumns, propeller shafts and pump shafts, heat exchangers, brine heaters, sulfuric acid and hydrofluoric acid alkylation plants and other high corrosive and high temperature applications. The ASTM b127 uns n04400 composition includes 63% nickel and 28% copper which allows it to be resistant to strong acids such as the sulfuric acid. The uns n04400 Plate operates at steam and heater elements because it has a high melting point of 1350 degrees Celsius. Latest price list of Titanium Gr 2 Plate

| ASTM Specification | ASTM A240 / ASME SA240 |

|---|---|

| Standard | MSRR, AMS, BS, ASTM A240 / ASME SA240 |

| Length & Sizes | 1000 mm x 2000 mm, 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1250mm x 2500mm, 1500mm x 3000mm to 6000mm, 2000mm x 4000mm to 6000mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm, 2m, 2.44m, 3m, 36" X 120" or 48" X 144", 4' x 8', Cut to size available |

| Thickness | 0.1mm to 100 mm Thk |

| Width | 10-2500mm |

| Hardness | Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc. |

| Temper | Annealed |

| Condition | Polished on both sides |

| Finish | Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) |

| Stock in form of | Plate, Sheet, Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Clad Plate, Rolling Sheet, Flat Sheet, Rolling Plate, Flat Shim, Blank (Circle), hot rolled, cold rolled, annealed, soft annealed, descaled, sheared, tread plate, Checker Plate |

| Value Added Service | Cladding, Heat Treatment, Annealed, Pickling, Polish, Rolling, Cutting, Bending, Forging, Minor Fabrication Etc. |

| Dealers & Distributor of | SAIL, ESSAR, JINDAL, TATA, BHUSHAN, INDIAN, POSCO, JISCO, TISCO, LISCO, BAOSTEEL IMPORTED material |

| Test Report |

|

| Profiling |

To provide a full profiling service we use numerous profiling methods including:

|

| Specialized in |

|

| We offer a comprehensive services designed to add value to your project: plasma cutting, waterjet cutting, laser cutting, bending and mechanical processing, edge preparation, welding, sawing and shearing. | |

| Grade | Ti | C | Fe | H | N | O | Al | V |

|---|---|---|---|---|---|---|---|---|

| Ti Grade2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | – | – |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 8.8 g/cm3 | 1350 °C (2460 °F) | Psi - 35,000 , MPa - 240 | Psi - 80,000 , MPa - 550 | 40 % |

FLOTECH METAL ALLOY INC IS LEADING MANUFACTURE, EXPORTERS, STOCKIST, SUPPLIERS OF TITANIUM GR2 FASTENERS.

The benefits of using 2.4360 (alloy 400) Bolts includes its high strength and

excellent corrosion resistance. The properties of the ASTM F467 400 Monel is

retained in a wide range of acidic and alkaline environments. Alloy 400 Bolts are

well suited for applications in reducing conditions.

Titanium Gr 2 has good ductility and thermal conductivity. Typically, Alloy 400

Fasteners finds application in chemical and hydro-carbon processing’s, marine

engineering, heat exchangers, valves and pumps. This is because the Titanium Gr 2 Bolts

and Nuts are resistant to deterioration in both chemical as well as marine

environments. Mostly, Titanium Gr 2 Socket Head Cap Screws are used in alkylation units,

specifically in the reacting section, where the fasteners are in contact with

concentrated hydrofluoric acid.

| Material | Titanium Gr 2 Alloy Fasteners |

|---|---|

| Titanium Gr 2 Fasteners ASTM / ANSI | ASTM F467 / ASME SF467 |

| Size of Titanium Gr 2 Fasteners | M02 to M160 |

| Length of Titanium Gr 2 Fasteners | 3 mm to 200 mm |

| Titanium Gr 2 Fasteners Threads: | BSW, UNC, BSF, UNF METRIC, or as required |

| M3, M14, M2.5, M2, M12, M5, M6, M4, M20, M16, M30, M24, M36, M8, M10 etc. | |

| Titanium Gr 2 Fasteners Standard: |

JIS, ASTM,BS, GB, DIN, IS, ISO

DIN: DIN 931, DIN 970, 934 DIN DIN 933 UTS – Unified Thread Standard : NPTF, UNS, NPT, UNF, UNC, UNEF ISO – International Organization for Standardization : ISO 4033 ,ISO 4032, JIS standards |

| Widely Use Titanium Gr 2 Bolts Types | Titanium Gr 2 Hex Head Bolt, Hex Bolt, Square Bolt, Eye Bolt, T Bolt, U Bolt, Lag Bolt, Counter sunk Bolt etc. |

| Widely Use Titanium Gr 2 Nut Types | Titanium Gr 2 Coupling Nut, Hex Head Nut, Wing Nut, Square Nut, Panel Nut, T Nut, Acorn Nuts, Dome Nut, Eye Nut, Lock Nut etc. |

| Widely Use Titanium Gr 2 Screw Types | Titanium Gr 2 Threaded Screw, Hex Head Screw, Socket Head Screw, Socket Set Screw, Blind Rivet, Concrete Screw, Shoulder Screw, Anchor Screw, Panel Screw, Machine Screw etc. |

| Widely Use Titanium Gr 2 Washer Types | Titanium Gr 2 Lock Washer, Machine Washers, Star Washers, Sealing Washer, Split Washer etc. |

| Widely Use Titanium Gr 2 Studs Types | Titanium Gr 2 Double Ended Studs, Threaded Tod, Tie Bars, Tie Rodsetc. |

| Titanium Gr 2 bolts Scope of Manufacture |

|

| Titanium Gr 2 Fasteners In Form of: | Square, Round, Threading as per Gauge,Round Etc. |

| Test Certificate of Monel Bolting : | EN 10204 / 3.1 |

| Finishing of Titanium Gr 2 Fasteners: | Zinc (yellow, white, blue, black), black oxide, Dacroment, Geometry, nickel plated, anodizing, plated zinc-nickel, Stainless steel: Passivated Bright Zinc Plated (BZP), Self-Colour, Hot Dip Galvanised (HDG), Stainless Steel, Sherardized,Mechanically Applied coating and some special one like DACROMET |

| Titanium Gr 2 Fasteners Production process | hot forging M24-M100, M2-M24: Cold Froging for Customized connecting element machining and CNC |

| Titanium Gr 2 bolts Head drive: | Six-Lobe, Phillips/Slot, Slotted, Phillips etc |

| Titanium Gr 2 bolts Origin and service-region: | European Origin of are Western European. However projects with eastern origin are possible on request. |

| Surface Coating of Titanium Gr 2 Fasteners materials: |

|

| Top Manufacturers of Fasteners | SPAX® Screws, EBY Fastener, Sundaram Kundan, GKW, Infasco, Precision, APL, Unbrako,Etc. |

| Packing of Titanium Gr 2 Fasteners: | In Bulk: pallet, Canton, Small Carton / Boxs / Pallet, or customer request |

| Specialized manufacturer of | Titanium Gr 2 High Tensile Fasteners, Bolts |

| Titanium Gr 2 Fasteners Test Certificates |

|

|

Properties

|

Metric

|

Imperial

|

|

Tensile strength(annealed)

|

517-620 MPa

|

75-90 ksi

|

|

Yield strength

|

172-345 MPa

|

25-50 ksi

|

|

Modulus of elasticity

|

179 GPa

|

26000 ksi

|

|

Poisson’s ratio

|

0.32

|

0.32

|

Titanium Gr 2 |

C |

Ti |

N |

Fe |

H |

O |

V |

Al |

0.1 max |

99.2 min |

0.03 max |

0.3 max |

0.015 max |

0.25 max |

– |

– |

We exports and supply titanium Gr2 pipes,pipe

fittings, tubes, flanges, round bars, sheet, plates, fasteners, valves in

Andaman and Nicobar Islands Andhra Pradesh Arunachal Pradesh Assam Bihar Chandigarh

Chattisgarh Chhattisgarh Dadra and Nagar Haveli Daman and Diu Delhi Goa Gujarat

Haryana Himachal Pradesh Jammu and Kashmir Jharkhand Jamshedpur Karnataka Kerala

Lakshadweep Madhya Pradesh Maharashtra Manipur Meghalaya Mizoram Nagaland Orissa

Odisha Puducherry Punjab Rajasthan Sikkim Tamil Nadu Telangana Tripura Uttarakhand

Uttaranchal Uttar Pradesh West Bengal

Adilabad Agartala Agra Ahmedabad Ahmednagar Ajmer Akola Alappuzha Aligarh Allahabad

Alleppey Alok City Aluva Alwar Alwaye Amalapuram Ambala Ambarnath Ambattur Ambernath

Ambur Amravati Amritsar Anand Anantapur Anantapuramu Angul Anjar Ankleshwar

Anklesvar Asansol Aurangabad Avadi Baddi Bagalkot Bahadurgarh Baharampur Ballari

Ballarpur Bangalore Bardhaman Bardoli Bareilly Barrackpore Bathinda Becharaji

Belagavi Belgaum Bellary Bengaluru Berhampore Berhampur Bhadravathi Bhadravati

Bhadreswar Bhagalpur Bharatpur Bharuch Bhatapara Bhatpara Bhavnagar Bhilai Bhilwara

Bhimavaram Bhiwadi Bhiwandi Bhiwani Bhopal Bhubaneswar Bhuj Bidar Bijapur Bikaner

Birlanagar Bokaro Bokaro Steel City Bongaigaon Brahmapur Broach Budge Budge

Bulandshahr Burnpur Calcutta Calicut Chaibasa Champdani Chandigarh Chandrapur

Channapatna Charkhi Dadri Chennai Cherthala Chikkamagaluru Chinchwad Chittaranjan

Chittoor Cochin Coimbatore Cuddalore Cuttack Dalkhola Dalmianagar Damanjodi Dandeli

Dankuni Darbhanga Darjeeling Davanagere Davangere Dehradun Delhi Dewas Dhanbad

Dhanbad City Dharmapuri Dharwad Dhule Dibrugarh Digboi Dindigul Dum Dum City

Durgapur Eluru Ennore Ernakulam Erode Faridabad Firozabad Gadchandur Gajraula

Gandhidham Gandhinagar Gaya Ghaziabad Goa Gorakhpur Gulbarga Guntur Gurgaon Gurugram

Guwahati Gwalior Habra Haldia Haldwani Halisahar Haora Haridwar Hassan Hazaribagh

Hisar Hooghly Hosapete Hosdurg Hoshiarpur Hospet Hosur Howrah Hubballi Hubli Hugli

Hyderabad Ichalkaranji Idukki Township Indore Induru City Jabalpur Jagatdal Jaipur

Jajpur Jalandhar Jalgaon Jammu Jamnagar Jamshedpur Jangipur Jetpur Jhansi Jharia

Jharsuguda Jind Jodhpur Jorhat Junagadh Kadapa Kagithapuram Kaithal Kakinada

Kalaburagi Kalburgi Kalimpong Kalinga Kalinga Nagar Kalpakkam Kalyan Kalyani

Kamarhati Kanchrapara Kannur Kanpur Karimnagar Karnal Karur Kashipur Katwa Khammam

Khammamett Khandwa Kharagpur Khardaha Khargaon Kheda Kochi Kodagu Kolar Kolhapur

Kolkata Kollam Kollegal Kollegala Koodankulam Koraput Korba Kota Kottayam Kozhikode

Kudankulam Kunnamkulam Kurnool Kurukshetra Latur Lucknow Ludhiana Madanapalle

Madurai Mahesana Malappuram Malda Malegaon Mandya Mangalore Mangaluru Manjeri Manmad

Margao Mathura Medinipur Meerut Mehsana Mirzapur City Modinagar Mohali Moradabad

Morbi Morvi Mumbai Muvattupuzha Muzaffarnagar Muzaffarpur Mysore Mysuru Nadiad

Nagaon Nagda Nagercoil Nagpur Naihati Nalgonda Nandambakkam Nanded Waghala Nandyal

Nandyala Nangal Narnaul Nashik Navi Mumbai Navsari Neemuch Nellai Nellore Nepanagar

New Delhi Neyveli Nimach Nizamabad Noida Noonmati Ongole Ooty Padajhar Khurd

Palakkad Palghar Palghat Pali Palwal Panchkula Panihati Panipat Panjim Panna

Paradeep Patiala Patna Perambra Perambur Pimpri Pimpri-Chinchwad Pinjore Pithampur

Prayagraj Punalur Pune Raebareli Raichur Raiganj Raigarh Raipur Rajahmundry Rajkot

Rampurhat Ranchi Rayagada Renukoot Rewa Rewari Rishikesh Rishra Rohtak Roorkee

Rourkela Rudrapur Rupnarayanpur Saharanpur Salem Sambalpur Sangli Satara

Secunderabad Seoni Shahdara Shamnagar Shantiniketan Shibpur Shimoga Shivamogga Sikar

Silchar Siliguri Silvassa Sindri Singhbhum Sirpur Sirsa Sivakasi Sodepur Solapur

Sonipat Sreerampur Sri City Sri Ganganagar Sriharikota Srikakulam Srinagar

Sriperumbudur Surat Surendranagar Suri Tambaram Tanuku Tarapur Thane Thanjavur

Thiruvananthapuram Thiruverumbur Thodupuzha Thoothukudi Thrissur Tinsukia

Tiruchirappalli Tirunelveli Tirupati Tiruppur Tiruvalla Titagarh Tribeni Trichy

Trivandrum Trombay Tumakuru Tumkur Tuticorin Udaipur Udhana Udupi Ujjain Unnao

Vadodara Valsad Vandalur Vapi Varanasi Vellore Veraval Vijayanagara Vijayapura

Vijayawada Villupuram Viluppuram Visakhapatnam Vizhuppuram Vizianagaram Warangal

Warora Wayanad Yamunanagar Zaina Kot

Afghanistan Albania Algeria Andorra Angola Antigua and Barbuda Argentina Armenia

Australia Austria Azerbaijan Bahamas Bahrain Bangladesh Barbados Belarus Belgium

Belize Benin Bhutan Bolivia Bosnia and Herzegovina Botswana Brazil Brunei Bulgaria

Burkina Faso Burundi Cambodia Cameroon Canada Cape Verde Central African Chad Chile

China Colombia Comoros Congo Costa Rica Cote D'Ivoire Croatia Cuba Cyprus

Czechia-Czech Republic Denmark Djibouti Dominican Republic Ecuador Egypt El Salvador

England Equatorial Guinea Eritrea Estonia Eswatini-Swaziland Ethiopia Europe Fiji

Finland France Gabon Gambia Georgia Germany Ghana Greece Grenada Guatemala

Guinea-Bissau Guyana Haiti Holy See Honduras Hong Kong Hungary Iceland India

Indonesia Iran Iraq Ireland Israel Italy Jamaica Japan Jordan Kazakhstan Kenya

Kiribati Kosovo Kuwait Kyrgyzstan Laos Latvia Lebanon Lesotho Liberia Libya

Liechtenstein Lithuania Luxembourg Macau Madagascar Malawi Malaysia Maldives Mali

Malta Marshall Islands Mauritania Mauritius Mexico Micronesia Moldova Monaco

Mongolia Montenegro Morocco Mozambique Myanmar-Burma Namibia Nauru Nepal Netherlands

New Zealand Nicaragua Niger Nigeria North Korea North Macedonia Norway Oman Pakistan

Palau Palestine Panama Papua New Guinea Paraguay Peru Philippines Poland Portugal

Puerto Rico Qatar Romania Russia Rwanda Saint Kitts and Nevis Saint Lucia Saint

Vincent and the Grenadines Samoa San Marino Sao Tome and Principe Saudi Arabia

Senegal Serbia Seychelles Sierra Leone Singapore Slovakia Slovenia Solomon Islands

Somalia South Africa South Korea South Sudan Spain Sri Lanka Sudan Suriname Sweden

Switzerland Syria Taiwan Tajikistan Tanzania Thailand Timor-Leste Togo Tonga

Trinidad and Tobago Tunisia Turkey Turkmenistan Tuvalu Uganda Ukraine United Arab

Emirates UAE United Kingdom United States US Uruguay Uzbekistan Vanuatu Vatican City

Venezuela Vietnam Yemen Zambia Zimbabwe

MIDDLE EAST : Saudi Arabia Iran Ira Qatar Bahrain Oman Kuwait Turkey Yemen Syria

Jordan Cyprus

ASIA : Singapore Malaysia Indonesia Thailand Vietnam South Korea Japan Sri Lanka

Maldives Bangladesh Myanmar Taiwan Cambodia

EUROPE : Russia Norway Germany France Italy UK Spain Ukraine Netherlands Belgium

Greece Czech Republic Portugal Hungary Albania Austria Switzerland Slovakia Finland

Ireland Croatia Slovenia Malta

AFRICA : Nigeria Algeria Angola South Africa Libya Egypt Sudan Equatorial Guinea the

Republic Of Congo Gabon

SOUTH AMERICA : Argentina Bolivia Brazil Chile Venezuela Colombia Ecuador Guyana

Paraguay Uruguay

NORTH AMERICA : US Canada Mexico Panama Costa Rica Puerto Rica Trinidad And Tobago

Jamaica Bahamas Denmark

Dealers | Distributors | Exporters | Importers | Manufacturers | Suppliers |

Stockists | Wholesalers